|

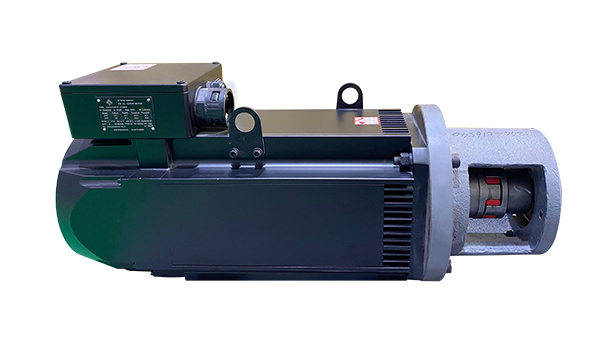

Energy saving

The electric melt adhesive is driven by a separate servo motor directly through the reducer, so there is no double loss of volumetric efficiency of oil pump and oil motor, no loss of pressure in the hydraulic pipe, which saves energy between a 15 % and a 25 %. % compared to servohydraulic cast adhesive.

|

|

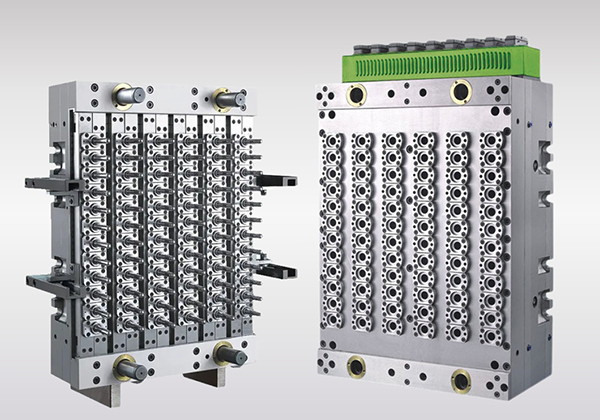

Synchronization It can realize the function of opening the mold and melting the glue synchronously, and shorten the product formation cycle (Needle valve hot runner mold cooperation is needed). |

|

|

Agility Directly driven by servo motor, low inertia and fast response.

|

|

Stability No influence of hydraulic pulse, stable screw speed, accurate measurement of molten adhesive. |

|

– OTHER SYSTEMS –

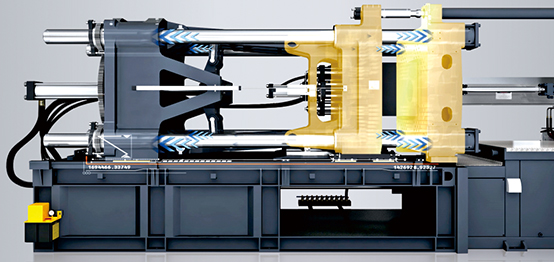

| Launch pad centering bearing | Mode clamping part | |

|

|

|

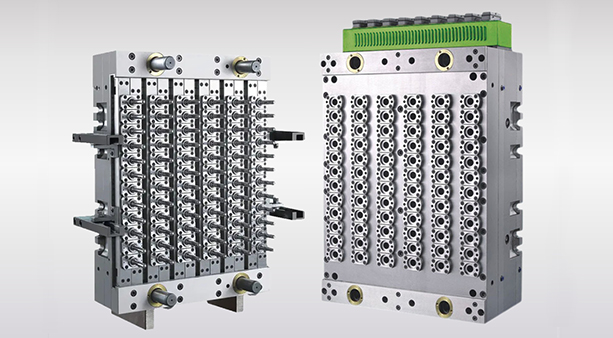

| Single injection queue table structure: based on conventional bearing positioning, A fixed bearing is added to improve the positioning of the glue injection assembly. This can effectively reduce the radial exhaust of the screw by melting the glue and improve the durability of the assembly and the bearing of the screw by melting the glue load. | Strictly check the parallelism between the fixed template and the dynamic template and the consistency of the clamping force on the four lines. | |

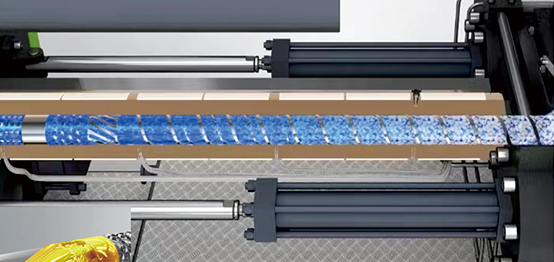

| Screw head assembly | Screw lamination | |

|

|

|

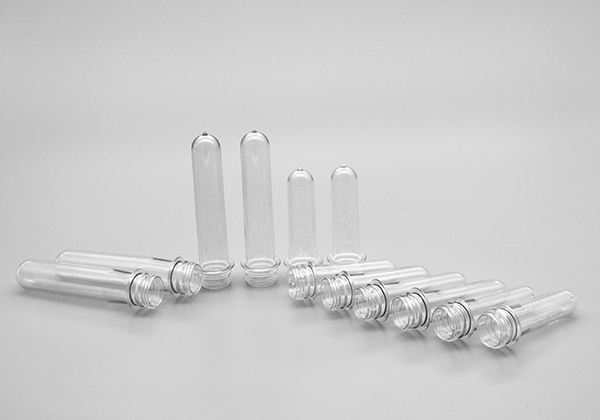

| The screw is made of high hardness material and electroplated, which makes the residual raw materials easy to clean, prevents black spots and variegated colors from injection molded products, and prevent the screw from being corroded. The screw head assembly is made of alloy material to ensure durability and precise check control. |

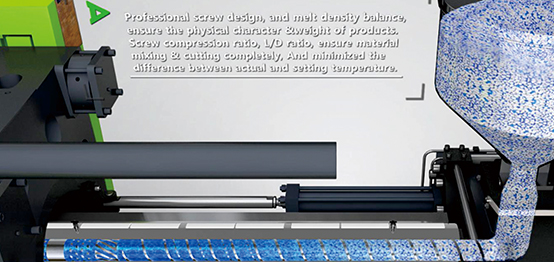

Professional screw assembly design can balance the melt density and ensure the consistency of physical properties and Gram weight of injection molded products. The screw compression ratio and length diameter ratio are designed to ensure that the raw materials are completely cut and mixed in the plasticizing process., and the difference between the actual temperature and the set temperature is minimized. |

Parameters of Electric Melt Adhesive Injection Molding Machine for DR-PET Bottle Preform

| Model | Unit | DR330-PET | DR400-PET | |||||||

| International standard model | 2310/3300 | 3250/3300 | 2310/4000 | 3250/4000 | 5275/4000 | 6630/4000 | 9240/4000 | |||

| Injection system | ||||||||||

| Screw diameter | mm | 83 | 90 | 95 | 90 | 95 | 100 | 110 | 120 | 130 |

| Screw length diameter ratio | L:D | 24:1 | 22:1 | 24:1 | 22:1 | 24:1 | 24:1 | 24:1 | 25:1 | 25:1 |

| Theoretical injection volume | cm³ | 2028 | 2384 | 3046 | 2384 | 3046 | 3376 | 4797 | 6443 | 8889 |

| Theoretical injection volume/PET | g | 2353 | 2767 | 3535 | 2767 | 3535 | 3917 | 5566 | 7476 | 10313 |

| oz | 82.4 | 96.8 | 123.7 | 96.8 | 123.7 | 137.1 | 194.8 | 261.7 | 361.0 | |

| injection speed | mm/s | 130 | 130 | 105 | 160 | 130 | 130 | 100 | 87 | 93 |

| injection rate | cm³/sec | 703 | 827 | 744 | 1017 | 921 | 1021 | 950 | 983 | 1234 |

| injection pressure | Mpa | 114 | 97 | 107 | 97 | 107 | 97 | 110 | 103 | 104 |

| injection stroke | mm | 375 | 375 | 430 | 375 | 430 | 430 | 505 | 570 | 670 |

| Screw speed | rpm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 100 |

| Mode clamping system | ||||||||||

| Holding force | kN | 3300 | 4000 | |||||||

| Clamping stroke | mm | 660 | 720 | |||||||

| Maximum opening distance of the template | mm | 1320 | 1470 | |||||||

| Tolerable matrix thickness | mm | 220-660 | 250-750 | |||||||

| Interior distance of the four braces | mm | 710×670 | 760×730 | |||||||

| Template size | mm | 995×955 | 1080×1050 | |||||||

| Mold positioning hole ruler | mm | Φ160H8 | Φ200H8 | |||||||

| Thimble strength | kN | 182 | 182 | |||||||

| thimble race | mm | 200 | 235 | |||||||

| Thimble number | pcs | 13 | 13 | |||||||

| Energy/electricity | ||||||||||

| System pressure | Mpa | 17.5 | 17.5 | |||||||

| oil pump motor | kW | 65 | 75 | 60+60 | ||||||

| Fusion adhesive motor | kW | 48 | 61 | 85 | 61 | 85 | 85 | 98 | 106 | 115 |

| Electrothermal power | kW | 37.0 | 38.8 | 49.3 | 38.8 | 49.3 | 51.8 | 59.7 | 68.0 | 73.7 |

| Temperature control area | Section | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 8 | 8 |

| Others | ||||||||||

| Fuel tank volume | L | 480 | 600 | 700 | ||||||

| Machine weight | Tons | 11.8 | 12.3 | 13.1 | 14.8 | 15.3 | 15.5 | 16.5 | 17.5 | 18.5 |

| Overall dimensions (L×W×H) | mxmxm | 7.02×1.6× 2.18 | 7.3×1.6× 2.18 | 7.46×1.6× 2.18 | 7.9×1.65× 2.15 | 8.2×1.65× 2.15 | 8.4×1.65× 2.15 | 8.8×1.65× 2.15 | 9.2×1.65× 2.15 | 9.7×1.65× 2.15 |