|

hinge

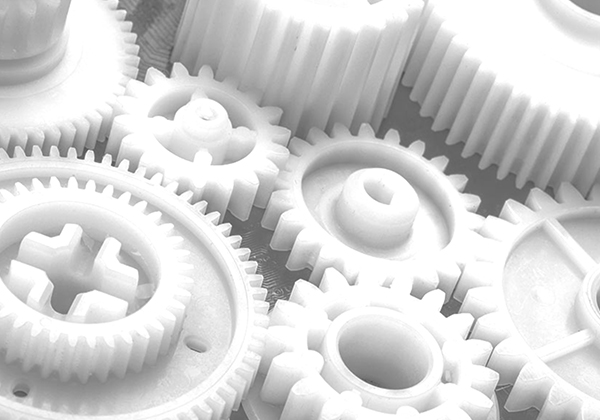

Characteristics: The hinge is new and optimized, and the design of wide body strength and large area is adopted, which achieves excellent effect of strength and speed.

|

|

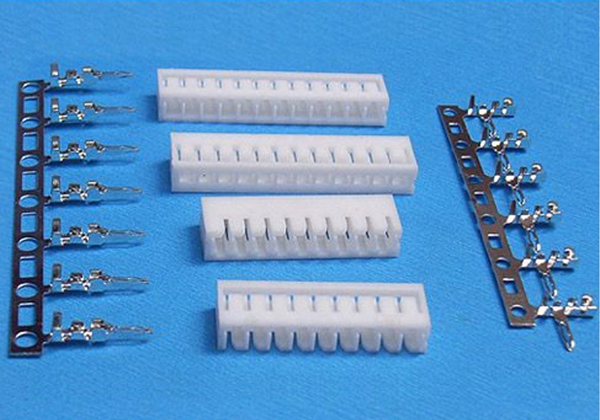

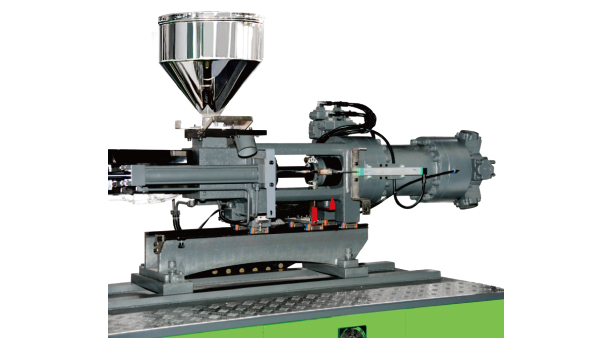

Launch pad Characteristics: Adopt single cylinder injection system commonly used in Europe, Japan and other regions, fusion pickup motor, injection tail board and design connected to the cylinder, you only need to push the screw when injecting (not all single cylinder injection design is this design) |

|

|

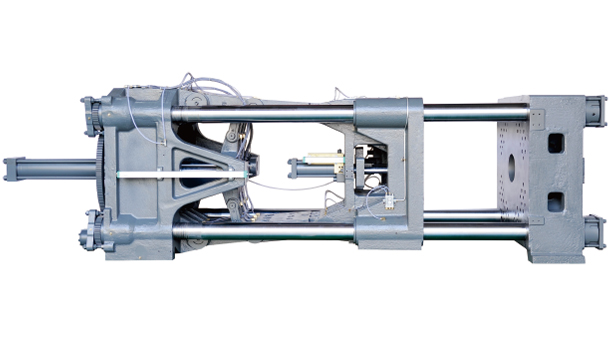

Transmission structure Characteristics: the most advanced transmission structure is adopted, and melt glue drive shaft and injection glue piston rod are designed separately.

|

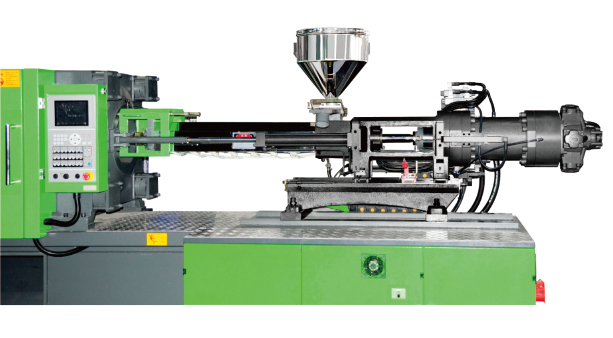

– OTHER SYSTEMS –

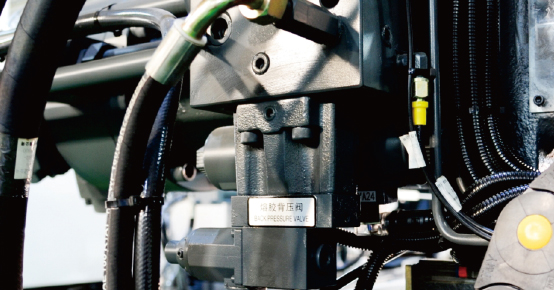

| Nozzle | Back pressure | |

|

|

|

| Equipped with nozzle shield to prevent personal injury caused by accidental injection of high temperature melt. | With numerical control of proportional back pressure and independent oil circuit, it is convenient, Quick and accurate adjust the back pressure of the melting adhesive, which is beneficial to control the melt density and facilitate statistical archiving of process data. | |

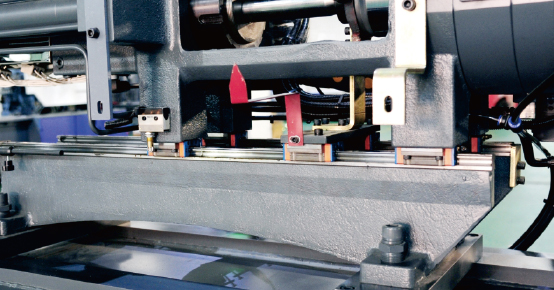

| linear guide rail | Comprehensive advantage | |

|

|

|

| The launching post adopts the linear ball guide rail, and the bracket adopts integrated casting to strengthen the rigidity. Resistance to mechanical movement is extremely low, the overall rigidity of the casting putter is strong, The casting biter has high precision and good durability. | Integrates the design advantages of the machinery, the oil circuit and electrical control, and has fast die opening speed, stable died opening and ending position, small impact and low voltage sensitive protection of die lock. | |

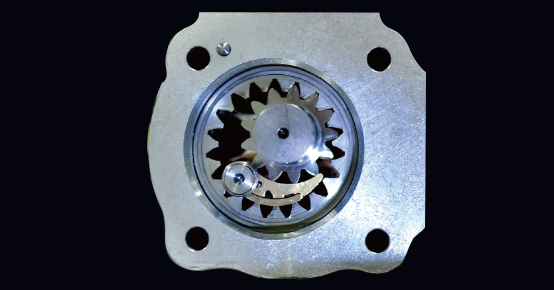

| Strict test | Internal gear pump | |

|

|

|

| The melt adhesive density and injection precision pass rigorous analysis and inspection before determining the design scheme to ensure the repeated weight accuracy of plastic products. | Equipped with the original internal gear pump imported from Germany, servo pump with pressure compensation, more stable outlet pressure, less internal leakage, high effective floor area ratio, energy saving and durability; The oil pump can withstand continuous working pressure up to 25MPa, which has obvious advantages for high speed and high pressure molding, low speed, high pressure molding and precision injection. | |

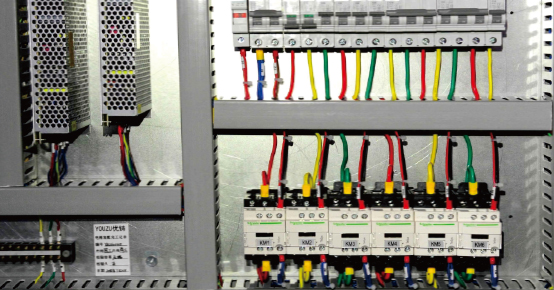

| Electric components | Complete inspection | |

|

|

|

| Adopting high quality Schneider/TE electrical components, combined with anti-interference circuit design, Lifespan is guaranteed and signal processing is more stable in frequent switch engagement. | Clamping force test and balance test adopt the path of full inspection, which is the performance of confidence in the machining precision and assembly quality of mechanical parts. Under the condition that sufficient clamping force can be provided, TIEBAR stretching deformation is smaller and the force is more uniform. |

Parameters of GS High Performance Injection Molding Machine

| Model | Unit | GS180 | ||||||||

| International standard model | 533/180 | 726/180 | 1052/180 | |||||||

| Release model | D530 | D720 | D1050 | |||||||

| Screw number | A | B | C | A | B | C | A | B | C | |

| Screw diameter | mm | 36 | 42 | 46 | 42 | 46 | 52 | 46 | 52 | 60 |

| Screw length diameter ratio | L:D | 22 | 22 | 20.1 | 22 | 22 | 19.5 | 22 | 22 | 19.1 |

| injection pressure | kg/c㎡ | 2647 | 1944 | 1621 | 2383 | 1987 | 1555 | 2533 | 1982 | 1489 |

| Injection weight (PS) | g | 181 | 247 | 296 | 274 | 329 | 420 | 374 | 478 | 636 |

| oz | 6.3 | 8.6 | 10.4 | 9.6 | 11.5 | 14.7 | 13.1 | 16.7 | 22.3 | |

| injection speed | mm/s | 150 | 150 | 150 | 122 | 122 | 122 | 96 | 96 | 96 |

| Maximum injection rate | cc / sec | 153 | 208 | 249 | 170 | 203 | 260 | 160 | 204 | 272 |

| Theoretical injection volume | cc | 201 | 274 | 329 | 305 | 365 | 467 | 415 | 531 | 707 |

| injection stroke | mm | 198 | 198 | 198 | 220 | 220 | 220 | 250 | 250 | 250 |

| Lamination skill (PS) | kg/h | 86 | 131 | 162 | 98 | 122 | 171 | 93 | 130 | 189 |

| Lamination skill (PS) | g/sec | 24 | 36.3 | 45 | 27.3 | 33.9 | 47.5 | 25.8 | 36.2 | 52.4 |

| Maximum screw speed | r.p.m | 372 | 372 | 372 | 290 | 290 | 290 | 217 | 217 | 217 |

| Nozzle contact force | Tons | 4.4 | 4.4 | 4.4 | 5.8 | 5.8 | 5.8 | 5.8 | 5.8 | 5.8 |

| Mode clamping system | Five point hinge | |||||||||

| Holding force | Tons | 180 | 180 | 180 | ||||||

| Clamping stroke | mm | 455 | 455 | 455 | ||||||

| Maximum opening distance of the template | mm | 975 | 975 | 975 | ||||||

| Tolerable matrix thickness | mm | 180-520 | 180-520 | 180-520 | ||||||

| Internal distance of four lines (horizontal * vertical) | mm | 470×470 | 470×470 | 470×470 | ||||||

| Template size (horizontal * vertical) | mm | 700×700 | 700×700 | 700×700 | ||||||

| Die Positioning Hole Dimension | mm | Φ125H8 | Φ125H8 | Φ125H8 | ||||||

| Thimble strength | ton | 7.7 | 7.7 | 7.7 | ||||||

| thimble race | mm | 140 | 140 | 140 | ||||||

| Thimble number | pcs | 5 | 5 | 5 | ||||||

| Others | ||||||||||

| System pressure | kg/c㎡ | 175 | 175 | 175 | ||||||

| oil pump motor | kW | 32 | 32 | 32 | ||||||

| Electrothermal power | kW | 8.8 | 10.9 | 13.6 | ||||||

| Temperature control area | section | 4+1 | 4+1 | 4+1 | ||||||

| Fuel tank volume | L | 347 | 347 | 347 | ||||||

| Machine weight | Tons | 5.8 | 5.9 | 6.1 | ||||||

| Overall dimensions (LxWxH) | mxmxm | 5.41×1.3×1.98 | 5.56×1.3×1.98 | 5.78×1.3×1.98 | ||||||