|

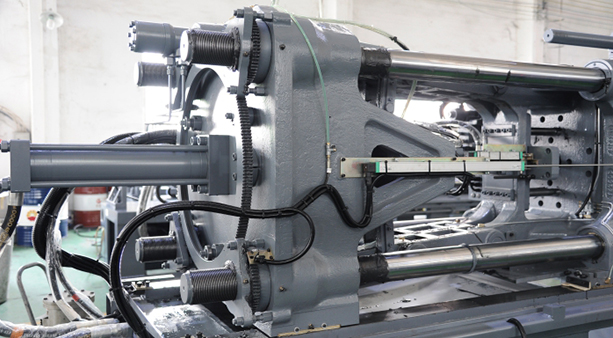

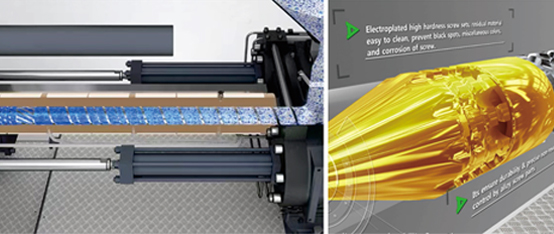

Adopt powder metallurgy special rubber barrel assembly, design screw compression ratio, flow length ratio, the three-stage ratio and other parameters according to the characteristics of raw materials and adopt high hardness alloy materials for material selection and implement strict tolerance standards.

This can make the melting adhesive temperature control stable, the quality of plasticizing mixture is high, the screw assembly is more wear-resistant and durable, and provides guarantee for high injection precision.

|

|

Optimize and adjust the template structure and thicken the template. Avoid loosening mold lock under high pressure, and the deformation of the mold blocking structure is small. Strengthen the hinge and vane of mold blocking machine and optimize the mold opening curve. Durability is improved and the speed of unlocking mold is faster. |

|

|

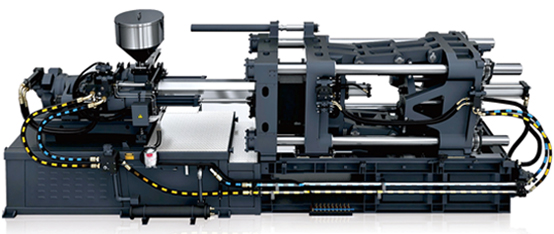

High power servo motor is used to match high torque servo motor, and the permanent magnet adopts the highest SH level. The design orientation of this power configuration is low speed and high torque, which has sufficient overload capacity and stable reliability test under harsh conditions.

|

|

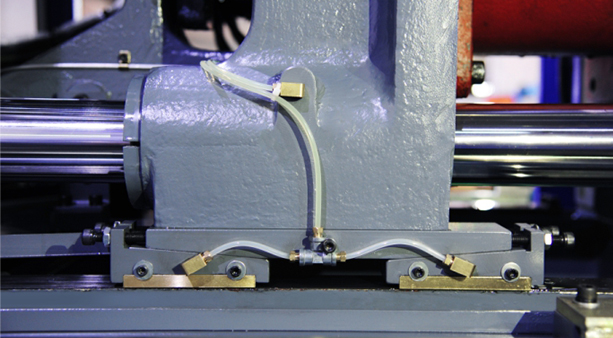

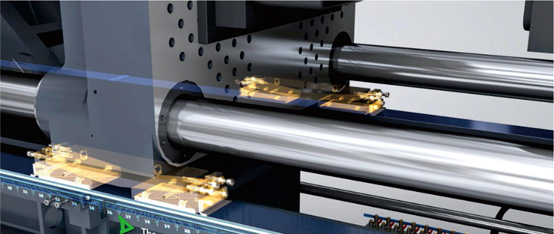

Dynamic footbed is designed with double sliding feet, and the stress area of the alloy copper plate is increased to reduce the pressure. It is more durable than traditional single sliding foot, and can support the opening and closing die with high speed and high load. Excellent bearing support ratio effectively ensures the consistency of hinge and bat stress. |

|

– OTHER SYSTEMS –

| Screw head assembly | linear guide rail | |

|

|

|

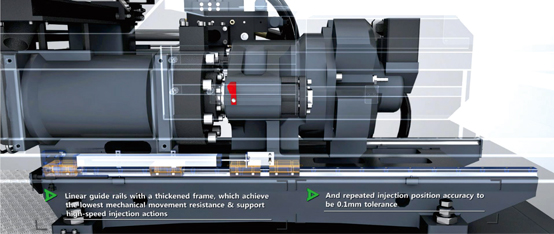

| The screw is made of high hardness material and electroplated, which makes the residual raw materials easy to clean, prevents black spots and variegated colors from injection molded products, and prevent the screw from being corroded. | The injection position repetition accuracy is as high as 0.1 mm (use: tested under standard factory conditions) The launch bridge adopts linear guide rail with thickened bracket to realize the lowest action resistance and support high-speed injection response. |

|

| Sliding foot | Large diameter oil circuit | |

|

|

|

| Dynamic insole adopts alloy copper double-slide foot design, which has less resistance when opening and closing the jig at high speed and ensures the durability of the mechanical movement. | Adopt large diameter oil circuit control mode and low internal resistance to improve response beat and action repetition accuracy. |

Parameters of MIM powder molding injection molding machine

| Model | Unit | YZ90S-MIM | YZ120S-MIM | YZ160S-MIM | |||

| International standard model | 194/900 | 228/900 | 228/1200 | 439/1600 | |||

| Injection system | |||||||

| Screw diameter | mm | 22 | 26 | 26 | 28 | 31 | 36 |

| Screw length diameter ratio | L:D | 22:1 | 22:1 | 22:1 | 20.5:1 | 22:1 | 20.5:1 |

| Theoretical injection volume | cm³ | 62 | 86 | 86 | 100 | 142 | 191 |

| Theoretical injection volume | g | 326 | 456 | 456 | 528 | 752 | 1014 |

| oz | 11.4 | 15.9 | 15.9 | 18.5 | 26.3 | 35.5 | |

| injection pressure | Mpa | 316 | 257 | 257 | 221 | 273 | 203 |

| injection speed | mm/s | 214 | 188 | 236 | 236 | 196 | 196 |

| injection rate | cm³/s | 81 | 100 | 125 | 145 | 148 | 200 |

| injection stroke | mm | 162 | 162 | 162 | 162 | 188 | 188 |

| Screw speed | rpm | 276 | 276 | 345 | 345 | 372 | 372 |

| Mode clamping system | Five point hinge | ||||||

| Holding force | KN | 900 | 1200 | 1600 | |||

| Clamping stroke | mm | 320 | 360 | 425 | |||

| Maximum opening distance of the template | mm | 680 | 810 | 925 | |||

| Tolerable matrix thickness | mm | 130-360 | 145-450 | 160-500 | |||

| Internal distance of four lines (horizontal * vertical) | mm×mm | 360×360 | 410×410 | 460×460 | |||

| Template size (horizontal * vertical) | mm×mm | 550×550 | 600×600 | 670×670 | |||

| Mold positioning hole ruler | mm | ∅100H8 | ∅125H8 | ∅125H8 | |||

| Thimble strength | KN | 23 | 34 | 42 | |||

| thimble race | mm | 80 | 120 | 140 | |||

| Thimble number | pcs | 1 | 5 | 5 | |||

| Energy/electricity | |||||||

| System pressure | Mpa | 17.5 | 17.5 | 17.5 | |||

| oil pump motor | KW | 20 | 27 | 32 | |||

| Electrothermal power | KW | 5.5 | 6.5 | 6.5 | 9.8 | ||

| Temperature control area | Section | 5 | 5 | 5 | |||

| Others | |||||||

| Fuel tank volume | L | 160 | 185 | 230 | |||

| Machine weight | Tons | 3.1 | 3.7 | 4.6 | |||

| Overall dimensions (LxWxH) | mxmxm | 3.84×1.08×1.76 | 4.3×1.16×1.85 | 4.6×1.29×1.97 | |||