|

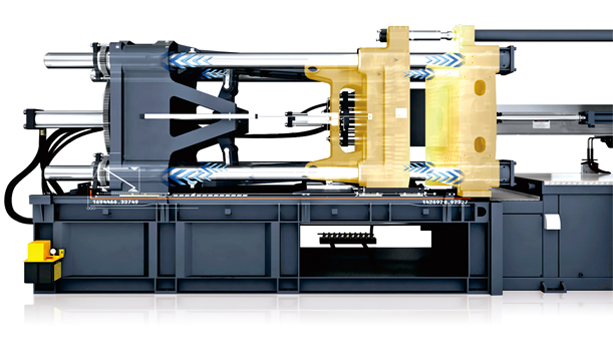

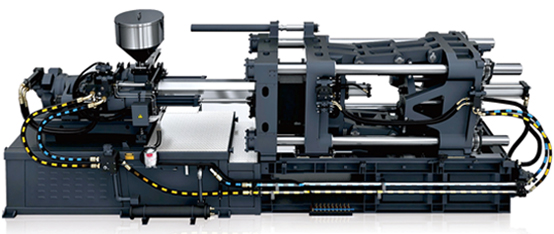

Mode clamping unit

Strictly check the parallelism between fixed template and dynamic template, and consistency of clamping force provided by four links.

|

|

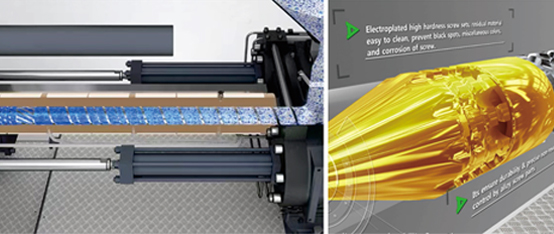

Launch pad centering bearing Single injection queue table structure: based on conventional bearing positioning, A fixed bearing is added to improve the positioning of the glue injection assembly. This can effectively reduce the radial exhaust of the screw by melting the glue and improve the durability of the assembly and the bearing of the screw by melting the glue load. |

|

|

Screw lamination The screw compression ratio and length diameter ratio are designed to ensure that the raw materials are completely cut and mixed in the plasticizing process., and the difference between the actual temperature and the set temperature is minimized.

|

– OTHER SYSTEMS –

| Screw head assembly | linear guide rail | |

|

|

|

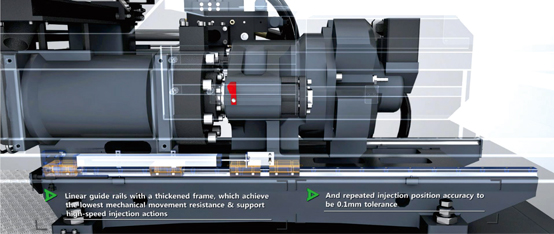

| The screw is made of high hardness material and electroplated, which makes the residual raw materials easy to clean, prevents black spots and variegated colors from injection molded products, and prevent the screw from being corroded. | The injection position repetition accuracy is as high as 0.1 mm (use: tested under standard factory conditions) The launch bridge adopts linear guide rail with thickened bracket to realize the lowest action resistance and support high-speed injection response. |

|

| Sliding foot | Large diameter oil circuit | |

|

|

|

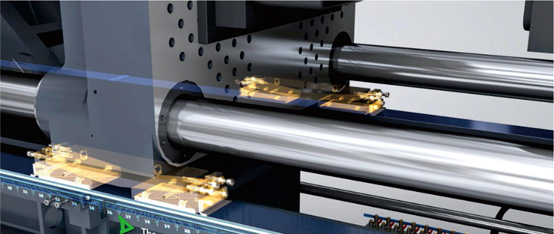

| Dynamic insole adopts alloy copper double-slide foot design, which has less resistance when opening and closing the jig at high speed and ensures the durability of the mechanical movement. | Adopt large diameter oil circuit control mode and low internal resistance to improve response beat and action repetition accuracy. |

Parameters of yj specialized injection molding machine for glasses

| Model | Unit | YJ90S-K | YJ90B-K | GS100S-K | GS100B-K | YJ160S-K | YJ160B-K | ||||

| International standard model | 280/900 | 280/900 | 280/1000 | 280/1000 | 805/1600 | ||||||

| Injection system | |||||||||||

| Screw diameter | mm | 28 | 31 | 28 | 31 | 28 | 31 | 28 | 31 | 40 | 40 |

| Screw length diameter ratio | L:D | 22:1 | 20:1 | 22:1 | 20:1 | 22:1 | 20:1 | 22:1 | 20:1 | 23:1 | 23:1 |

| Theoretical injection volume | CC | 74 | 91 | 74 | 91 | 74 | 91 | 74 | 91 | 265 | 265 |

| Injection weight (PS) | g | 79 | 97 | 79 | 97 | 79 | 97 | 79 | 97 | 284 | 284 |

| OZ | 2.8 | 3.4 | 2.8 | 3.4 | 2.8 | 3.4 | 2.8 | 3.4 | 9.9 | 9.9 | |

| injection rate | mm/s | 88 | 88 | 67 | 67 | 88 | 88 | 67 | 67 | 84 | 62 |

| injection rate | cm³ /sec | 54 | 66 | 41 | 51 | 54 | 66 | 41 | 51 | 106 | 78 |

| injection pressure | Mpa | 380 | 310 | 380 | 310 | 380 | 310 | 380 | 310 | 304 | 304 |

| injection stroke | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 211 | 211 |

| Screw speed | rpm | 230 | 230 | 175 | 175 | 230 | 230 | 175 | 175 | 240 | 175 |

| Mode clamping system | |||||||||||

| Holding force | kN | 900 | 900 | 1000 | 1000 | 1600 | 1600 | ||||

| Clamping stroke | mm | 320 | 320 | 340 | 340 | 425 | 425 | ||||

| Maximum opening distance of the template | mm | 680 | 680 | 720 | 720 | 925 | 925 | ||||

| Tolerable matrix thickness | mm | 130-360 | 130-360 | 140-380 | 140-380 | 160-500 | 160-500 | ||||

| Interior distance of the four braces | mmxmm | 360×360 | 360×360 | 360×360 | 360×360 | 460×460 | 460×460 | ||||

| Template size | mmxmm | 550×550 | 550×550 | 550×550 | 550×550 | 670×670 | 670×670 | ||||

| Thimble strength | kN | 23 | 23 | 34 | 34 | 42 | 42 | ||||

| thimble race | mm | 80 | 80 | 100 | 100 | 140 | 140 | ||||

| Thimble number | pcs | 1 | 1 | 5 | 5 | 5 | 5 | ||||

| Energy/electricity | |||||||||||

| System pressure | Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||

| oil pump motor | KW | 17 | 7.5 | 17 | 7.5 | 27 | 15 | ||||

| Electrothermal power | KW | 6.5 | 6.5 | 6.5 | 6.5 | 10.9 | 10.9 | ||||

| Temperature control area | Section | 5 | 5 | 5 | 5 | 5 | 5 | ||||

| Others | |||||||||||

| Fuel tank volume | L | 160 | 160 | 175 | 175 | 230 | 230 | ||||

| Machine weight | Tons | 3.1 | 3.1 | 3.8 | 3.8 | 4.7 | 4.7 | ||||

| Overall dimensions (LxWxH) | mxmxm | 3.84×1.08×1.76 | 3.84×1.08×1.76 | 4.62×1.15×1.86 | 4.62×1.15×1.86 | 4.59×1.29×1.97 | 4.59×1.29×1.97 | ||||