|

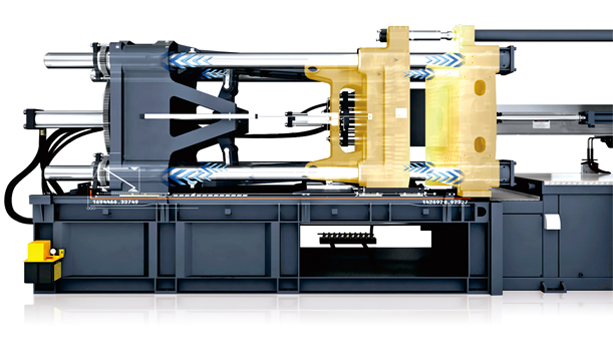

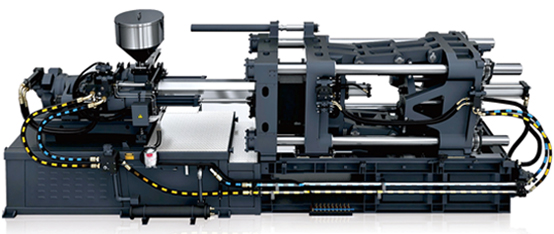

Mode clamping unit

Strictly check the parallelism between fixed template and dynamic template, and consistency of clamping force provided by four links.

|

|

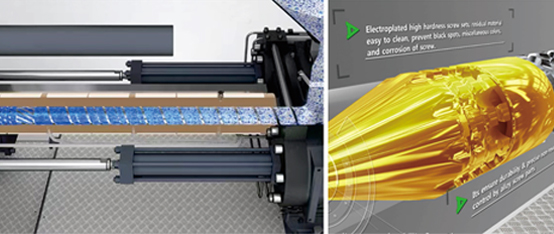

Launch pad centering bearing Single injection queue table structure: based on conventional bearing positioning, A fixed bearing is added to improve the positioning of the glue injection assembly. |

|

|

Screw lamination Professional screw assembly design can balance the melt density and ensure the consistency of physical properties and Gram weight of injection molded products.

|

– OTHER SYSTEMS –

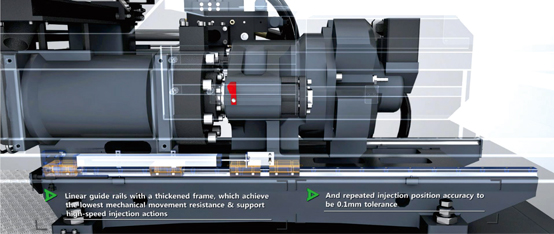

| Screw head assembly | linear guide rail | |

|

|

|

| The screw head assembly is made of alloy material to ensure durability and precise check control. | The injection position repetition accuracy is as high as 0.1 mm. (Use: Test under standard factory conditions) The launch launch adopts linear guide rail with thickened bracket to realize the lowest action resistance and support high speed injection response. |

|

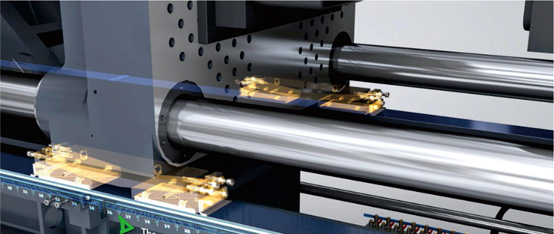

| Sliding foot | Large diameter oil circuit | |

|

|

|

| Dynamic insole adopts alloy copper double-slide foot design, which has less resistance when opening and closing the jig at high speed and ensures the durability of the mechanical movement. | Large diameter and low internal resistance oil circuit control mode is adopted to improve the response beat and the accuracy of action repetition. |

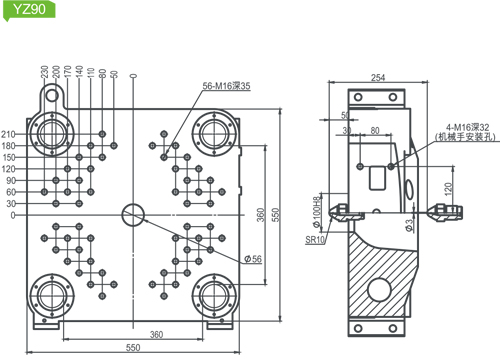

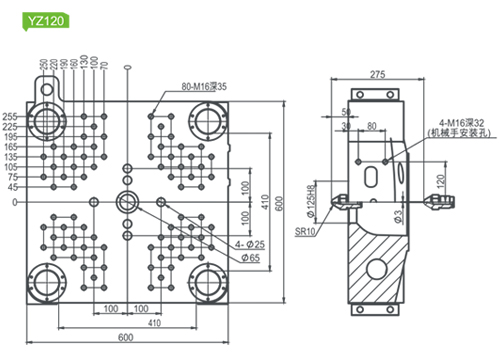

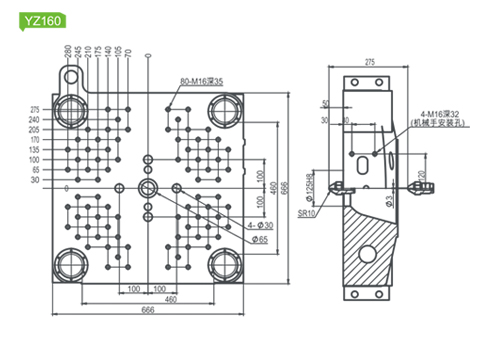

Parameters of YZ 3S Standard Injection Molding Machine

| Model | Unit | YZ90B-ⅢS | YZ120B-ⅢS | YZ160B-ⅢS | YZ200B-ⅢS | YZ260B-ⅢS | YZ320B-ⅢS | ||||||||||||||

| International standard model | 296/900 | 441/1200 | 660/1600 | 912/2000 | 1322/2600 | 1992/3200 | |||||||||||||||

| Injection system | |||||||||||||||||||||

| Screw type | U | A | B | C | U | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| Screw diameter | mm | 28 | 31 | 36 | 42 | 31 | 36 | 42 | 46 | 42 | 46 | 52 | 46 | 52 | 60 | 52 | 60 | 67 | 60 | 67 | 75 |

| Screw length diameter ratio | L:D | 20.5 | 23.2 | 20 | 17.1 | 20 | 23.4 | 20.1 | 18.3 | 22 | 20.1 | 17.8 | 23.3 | 20.6 | 17.8 | 24.6 | 21.3 | 19.1 | 24.6 | 22 | 19.7 |

| Theoretical injection volume | cc | 100 | 122 | 165 | 224 | 142 | 191 | 260 | 312 | 292 | 350 | 448 | 397 | 507 | 675 | 586 | 780 | 973 | 910 | 1135 | 1422 |

| Injection weight (PS) | g | 91 | 111 | 150 | 204 | 129 | 174 | 237 | 284 | 266 | 319 | 407 | 361 | 461 | 614 | 533 | 709 | 884 | 827 | 1031 | 1292 |

| oz | 3.2 | 3.9 | 5.2 | 7.1 | 4.5 | 6.1 | 8.3 | 9.9 | 9.3 | 11.2 | 14.2 | 12.6 | 16.1 | 21.5 | 18.6 | 24.8 | 30.9 | 29 | 36.1 | 45.2 | |

| injection pressure | Mpa | 297 | 242 | 180 | 132 | 310 | 230 | 169 | 141 | 226 | 188 | 147 | 230 | 180 | 135 | 226 | 169 | 136 | 219 | 175 | 140 |

| injection rate | cm³/sec | 53 | 65 | 88 | 119 | 62 | 83 | 113 | 136 | 106 | 127 | 162 | 130 | 166 | 221 | 189 | 251 | 313 | 293 | 366 | 458 |

| injection stroke | mm | 162 | 188 | 211 | 239 | 276 | 322 | ||||||||||||||

| Screw speed | rpm | 165 | 172 | 166 | 156 | 167 | 190 | ||||||||||||||

| Mode clamping system | |||||||||||||||||||||

| Holding force | kN | 900 | 1200 | 1600 | 2000 | 2600 | 3200 | ||||||||||||||

| Clamping stroke | mm | 320 | 360 | 425 | 485 | 540 | 620 | ||||||||||||||

| Maximum opening distance of the template | mm | 640 | 810 | 925 | 1035 | 1140 | 1280 | ||||||||||||||

| Tolerable matrix thickness | mm | 130-360 | 145-450 | 160-500 | 180-550 | 195-600 | 220-660 | ||||||||||||||

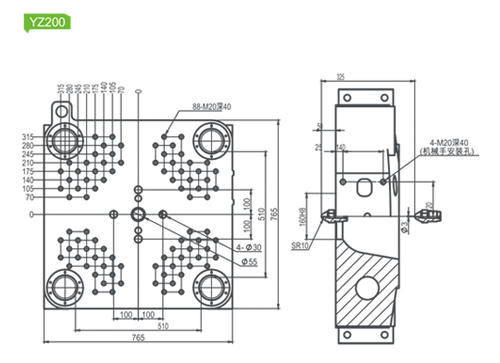

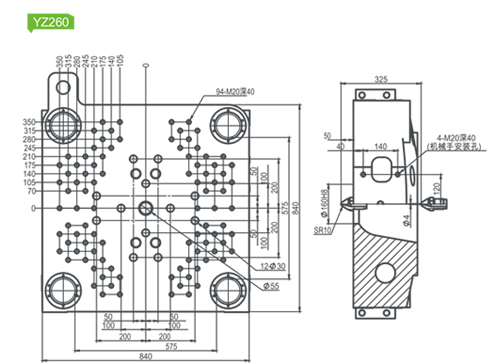

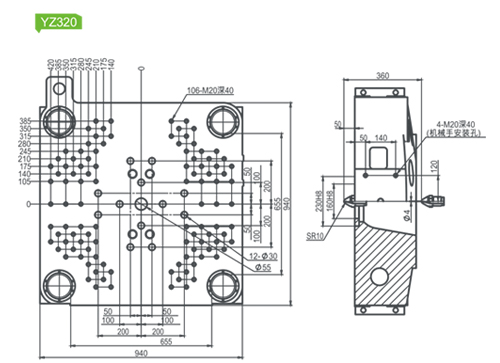

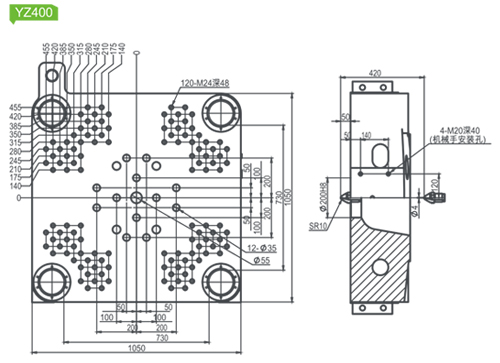

| Interior distance of the four braces | mm | 360×360 | 410×410 | 460×460 | 510×510 | 575×575 | 655*655 | ||||||||||||||

| Template size | mm | 550×550 | 600×600 | 670×670 | 765×765 | 840×840 | 940*940 | ||||||||||||||

| Mold positioning hole ruler | mm | Φ100H8 | Φ125H8 | Φ125H8 | Φ125H8 | Φ160H8 | Φ160H8 | ||||||||||||||

| Thimble strength | kN | 23 | 34 | 42 | 67 | 77 | 77 | ||||||||||||||

| thimble race | mm | 80 | 120 | 140 | 150 | 180 | 180 | ||||||||||||||

| Thimble number | pcs | 1 | 5 | 5 | 5 | 13 | 13 | ||||||||||||||

| Energy/electricity | |||||||||||||||||||||

| System pressure | Mpa | 14.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||||||||||||

| oil pump motor | kW | 7.5 | 11 | 15 | 18.5 | 22 | 42 | ||||||||||||||

| Electrothermal power | kW | 6.5 | 9.8 | 10.9 | 14.0 | 17.7 | 20.9 | ||||||||||||||

| Temperature control area | Section | 5 | 5 | 5 | 5 | 5 | 5 | ||||||||||||||

| Others | |||||||||||||||||||||

| Fuel tank volume | L | 130 | 170 | 210 | 250 | 370 | 450 | ||||||||||||||

| Machine weight | Tons | 3.1 | 3.8 | 4.7 | 6.2 | 8.5 | 11.1 | ||||||||||||||

| Overall dimensions (LxWxH) |

mxmxm | 3.84×1.08×1.76 | 4.3×1.16×1.85 | 4.59×1.29×1.97 | 5.19×1.36×1.94 | 6.13×1.49×2.06 | 6.65×1.60×2.18 | ||||||||||||||